We provide a full range of high-performance pulley lagging options designed to enhance conveyor efficiency, reduce maintenance, and extend the lifespan of both belts and pulleys. Our lagging products are developed to perform in the most demanding industrial environments.

Plain Pulley Lagging

Moontain’s Plain Pulley Lagging features a smooth rubber surface ideal for non-drive pulleys, especially on the dirty side of the conveyor belt. Designed for general-purpose applications, it protects pulleys from wear, reduces maintenance needs, and improves overall system reliability.

Features:

• Smooth rubber lagging surface

• Ideal for non-drive pulleys on the return side of the belt

• Bi-directional pulley rotation support

• Effective in shedding water from the belt surface

• Reversing drive pulley compatible

• Helps reduce spare pulley inventory

• High wear resistance for extended service life

• Enhances friction coefficient between pulley and belt

Specifications

• Thickness: 8mm – 20mm

• Width: 200mm – 2000mm

Diamond Pulley Lagging

Moontain’s Diamond Pulley Lagging includes a CN bonding layer for superior adhesion to the pulley surface. The diamond pattern enhances traction, making it suitable for drive pulleys in moderate to heavy-duty applications.

Advantages

• CN bonding layer ensures high bonding strength

• Improved grip and reduced belt slippage

• Water-shedding diamond groove design

• Designed for use with bi-directional and reversing pulleys

• Extended pulley and belt life

• Optimal for challenging environments with moisture or debris

Specifications

• Thickness: 8mm – 20mm

• Width: 200mm – 2000mm

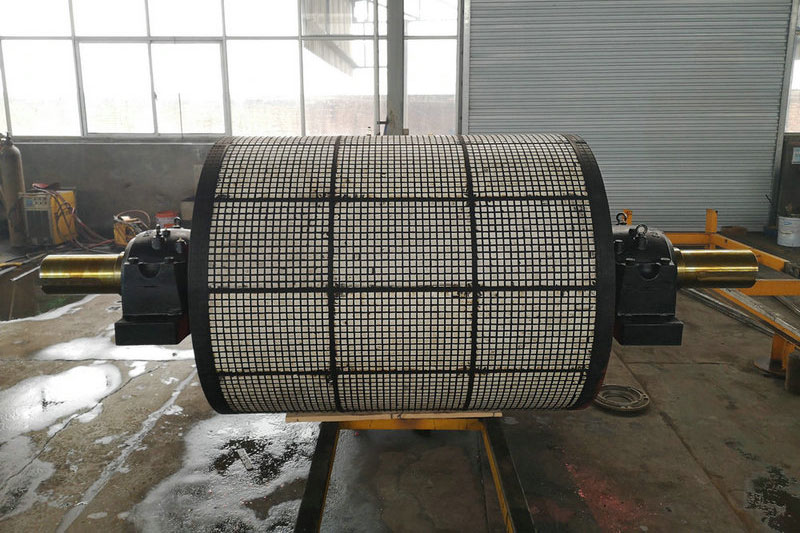

Ceramic Pulley Lagging

Moontain’s Ceramic Pulley Lagging is designed for high-friction and high-wear applications. This lagging integrates durable alumina ceramic tiles into the rubber matrix, providing exceptional performance in wet, muddy, and abrasive conditions. It is especially suitable for drive pulleys where conventional rubber lagging fails.

Advantages

• Eliminates belt slippage under harsh conditions

• Improves belt tracking and alignment

• Extends service life of both belt and pulley

• Outstanding abrasion resistance

• Reduces maintenance and unplanned downtime

• Can be installed using cold vulcanization methods

Specifications

• 12mm thickness x 200mm width (length customizable)

• 15mm thickness x 500mm width (length customizable)

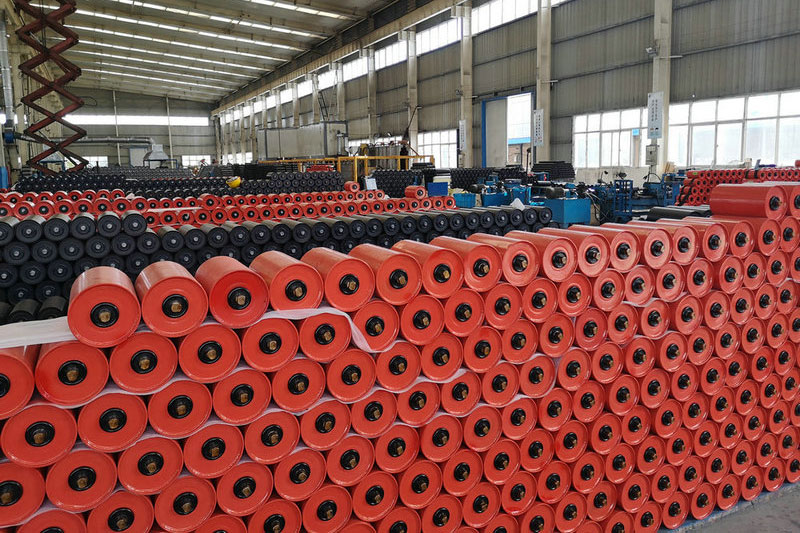

Replaceable Pulley Lagging

Moontain’s Replaceable Pulley Lagging is an innovative solution featuring a layered structure consisting of a wear-resistant rubber surface, bonded to a metal backing, and secured with a mechanical retainer system. This lagging can be installed directly on-site without removing the pulley, making maintenance quick and cost-effective.

Features

• On-site installation without pulley removal

• Simple and fast replacement process

• Durable rubber layer with extended service life

• Suitable for pulleys of various specifications

• Reduces downtime and labor costs

Specifications

• Available in 12mm, 15mm, and 20mm thicknesses