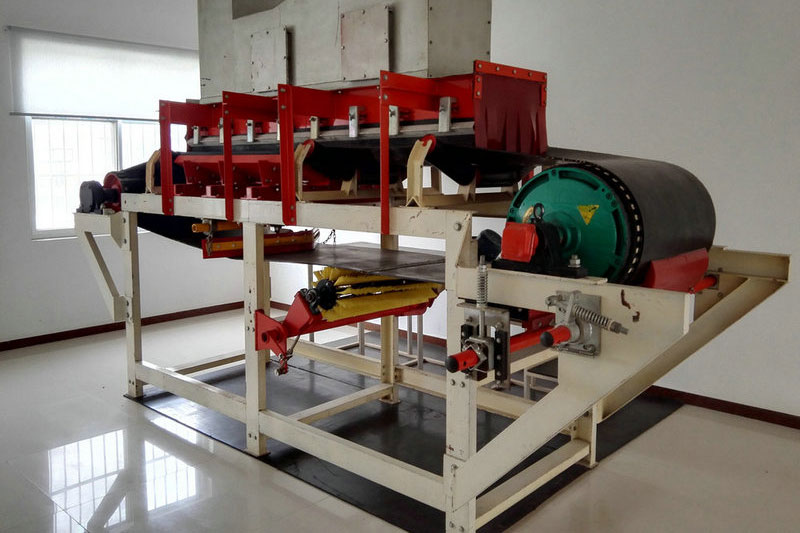

The primary cleaner plays a key role in the conveyor belt cleaning system, helping to keep the belt clean, reduce impurities, reduce material loss, reduce the burden on the secondary cleaner, and improve the efficiency of the entire conveyor system. These factors are important to ensure reliable operation of conveyor belt systems and reduce operating costs. We provide conveyor belt washing systems. Why do you need Primary Cleaner?

Problems Faced

a. Carryback: Material sticking to the conveyor belt and falling off along the return side.

b. Mistracking: The belt drifting to one side, causing material spillage, uneven belt wear, and potential damage to the system.

c. Belt Slip: When the head pulley fails to grip the belt effectively, often due to a loss of friction.

d. Spillage: Material spilling off the belt, especially at transfer and load points.

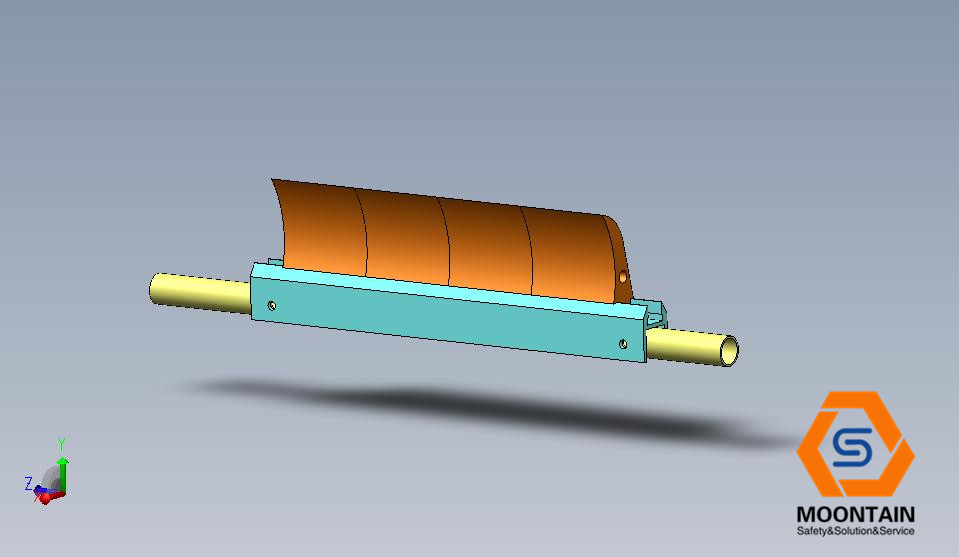

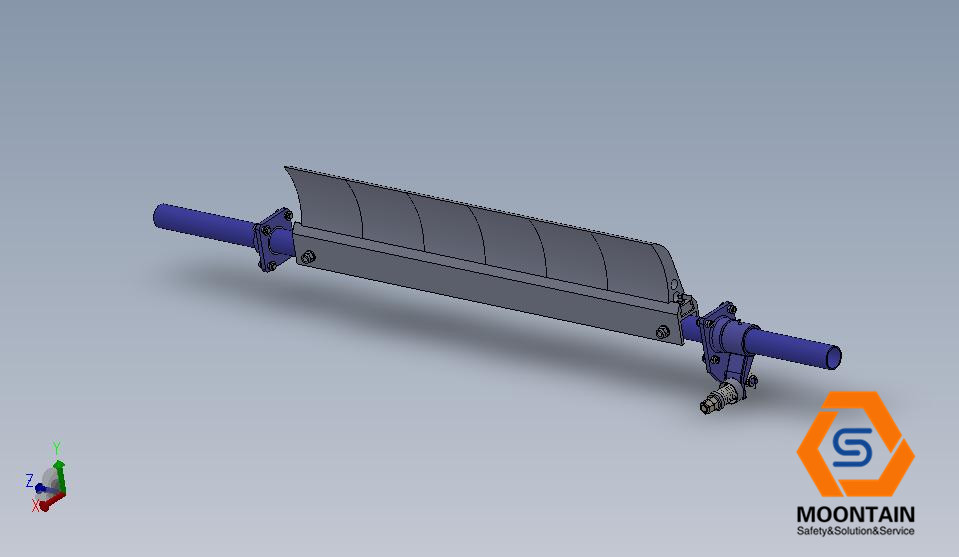

Primary Cleaner

Primary Cleaner is an important component in the conveyor belt cleaning system and has the following important functions:

Remove most impurities and materials: During use, the conveyor belt will accumulate various impurities, dust, mud and other materials, which may adhere to the belt, causing the belt surface to be uneven. The function of the primary cleaner is to remove these impurities and materials from the belt surface through scrapers, brushes or other mechanical devices to ensure that the belt remains clean.

Reduce material recycling and loss: When materials fall off or stick to the belt during transportation, it results in material loss and additional costs for cleanup. Primary cleaners can help reduce these losses and ensure materials are reliably transported to their destination.

Reduce the burden on secondary cleaners: Conveyor belt cleaning systems usually include multiple levels of cleaners, such as primary cleaners and secondary cleaners. The function of the primary cleaner is to minimize dirt and impurities on the material before it reaches the secondary cleaner. This helps extend the life of the secondary cleaner and maintenance intervals.

Improved system efficiency: Clean conveyor belt surfaces provide better friction, reducing the potential for belt slippage and abnormal wear. This helps increase the efficiency of the conveyor system, reducing downtime and repair costs.

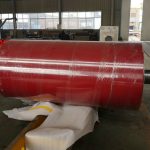

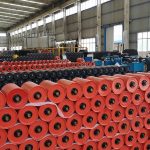

Moontain Primary Cleaner

a. Design and Durability: Moontain products have been designed and improved to withstand tough applications in various industries, including underground coal mining, port loading facilities, and heavy-duty work environments.

b. Consistent, Efficient Performance: These products aim to maximize uptime and reduce downtime by addressing issues like carryback, mistracking, belt slip, and spillage.

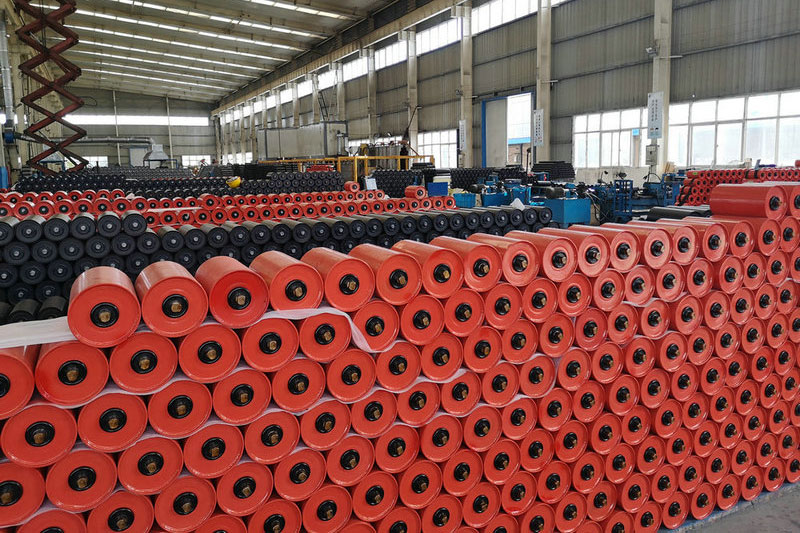

c. Lower Operation Costs: Moontain products offer better maintenance to protect conveyor parts from damage, which can result in cost savings in the long run.

d. Budget Savings: By increasing the lifetime of conveyor parts and reducing the need for repairs, Moontain products can help save both time and money.

Moontain products are positioned as a solution to common conveyor system challenges, offering durability, improved performance, cost savings, and reduced maintenance efforts. These benefits make them suitable for demanding industrial applications.