Reliable Hot Vulcanizing Solutions for Industrial Conveyor Belt Splicing

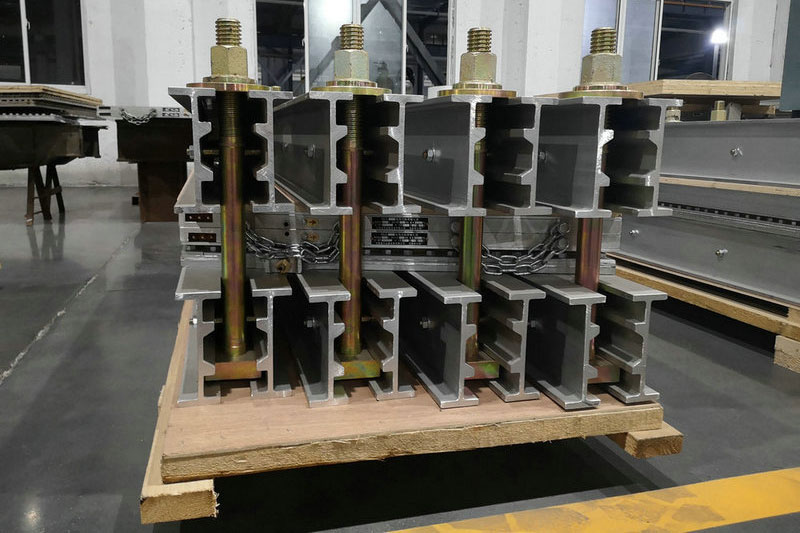

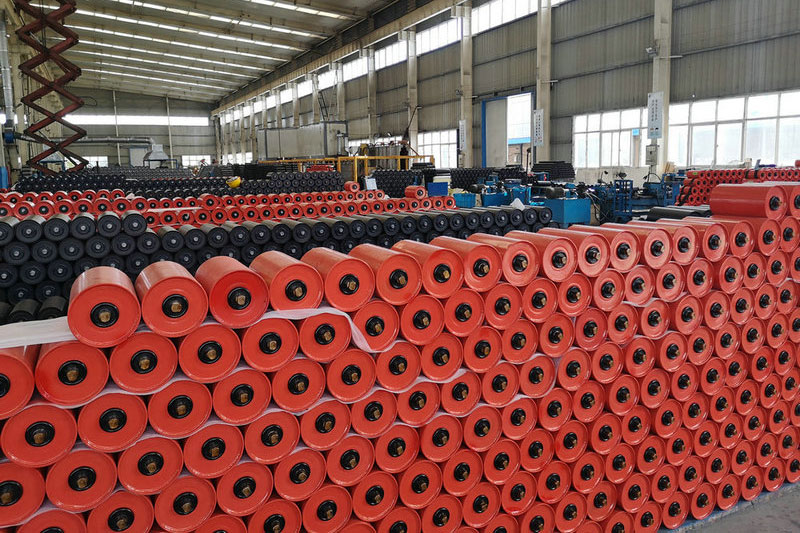

The Moontain Hot Vulcanizing Machine is engineered for the efficient splicing of various types of rubber conveyor belts, including EP belts, NN belts, and steel cord belts. Constructed with high-strength aluminum alloy, it is widely used across demanding industries such as metallurgy, mining, power plants, and ports, where durability and performance are critical.

Technical Specifications

-

Vulcanizing Pressure: 1.5 MPa (15 kg/cm²); optional 1.8 MPa (18 kg/cm²)

-

Vulcanizing Temperature: 145°C (adjustable)

-

Heating Time: Within 40 minutes

-

Temperature Uniformity: ±3°C across the working surface

-

Temperature Range: 0 ~ 200°C

-

Power Supply: 380V / 50Hz or 660V

Advantages

-

Intelligent Digital Control System

Moontain vulcanizers are equipped with an advanced full-automatic digital control system that ensures precise and uniform vulcanizing temperature, improving joint quality and minimizing human error.

-

High-Strength Aluminum Alloy Heating Plates

We use premium-grade aluminum alloy to manufacture the heating plates, ensuring excellent heat conductivity, reduced weight, and outstanding durability even under heavy industrial use.

-

Rapid Heating Performance

The machine heats from ambient temperature to the required vulcanizing temperature (145°C) in less than 30 minutes, significantly reducing downtime and increasing operational efficiency.

-

Optional Water Cooling System

A custom-designed water cooling system can be added to meet client-specific needs. It allows rapid cooling after vulcanization, improving safety and enabling faster turnover in high-demand environments.

Applications

Whether it’s splicing belts in steel plants, underground mining operations, power station coal lines, or port loading zones, Moontain vulcanizers deliver consistent and dependable results in the most challenging environments.