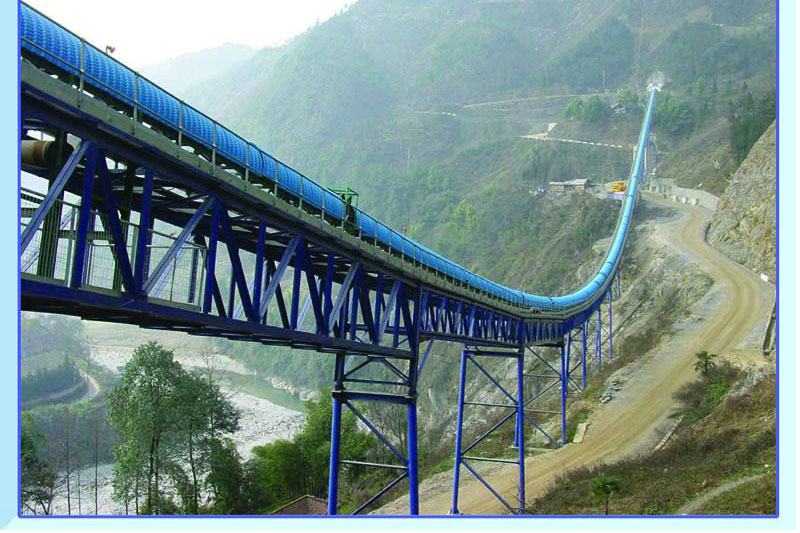

Moontain Long Distance Belt Conveyor

Cost-Efficient Bulk Material Transport Across Complex Terrains

Moontain’s Long Distance Belt Conveyor system offers an efficient, low-maintenance solution for bulk material transport across long distances — even in the most challenging terrains. Designed to minimize the need for intermediate transfer stations, this system provides a streamlined, environmentally friendly approach to large-scale bulk handling.

Available in both overland and curved conveyor configurations, our systems can be engineered to follow the natural topography, eliminating the need for extensive civil works and reducing environmental disruption.

Features and Benefits

-

Flexible Routing with No Terrain Limitations

Engineered to adapt to mountainous regions, valleys, rivers, or uneven landforms. The curved belt design allows the system to bypass obstacles and minimize land use.

-

True Long-Distance Capability

Moontain conveyors can span distances of tens of kilometers, making them ideal for mining, quarrying, and large industrial operations.

-

Eliminates Midway Transfer Stations

Continuous transportation from point A to point B without the need for intermediate handover or loading stations, significantly reducing energy usage and manpower.

-

Lower Capital and Operating Costs

By eliminating transfer points and minimizing structural requirements, total investment and long-term maintenance expenses are greatly reduced.

-

Eco-Friendly Transport Solution

Reduced noise, dust, and carbon emissions compared to truck transport. Ideal for environmentally sensitive areas and modern industrial standards.

Applications

-

Mining operations (coal, ore, aggregates)

-

Cement and quarry plants

-

Power plants and biomass facilities

-

Port terminals and bulk logistics hubs

-

Any scenario requiring large-volume, long-range, continuous bulk material transport

Why Moontain?

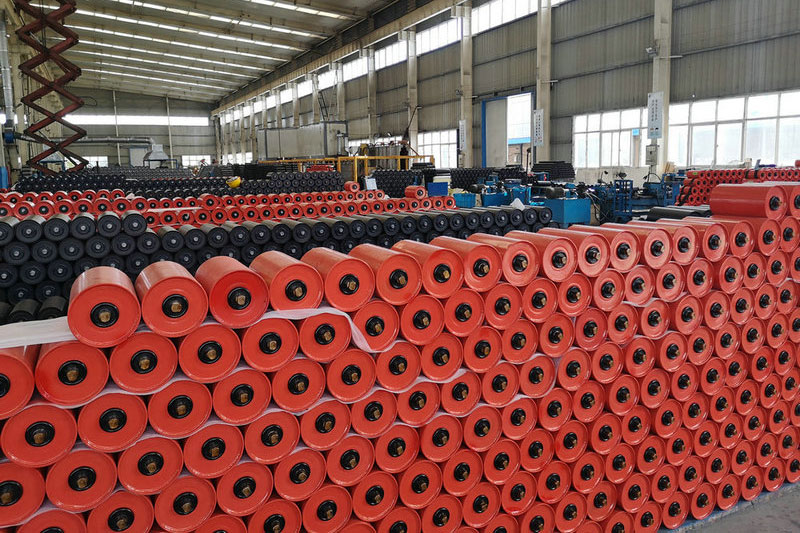

With deep experience in designing and delivering complete bulk conveying systems, Moontain provides fully customized solutions tailored to each site’s terrain, material type, and production goals. Our long-distance conveyors combine smart engineering, durable components, and field-proven reliability — ensuring smooth operation under the harshest industrial conditions.