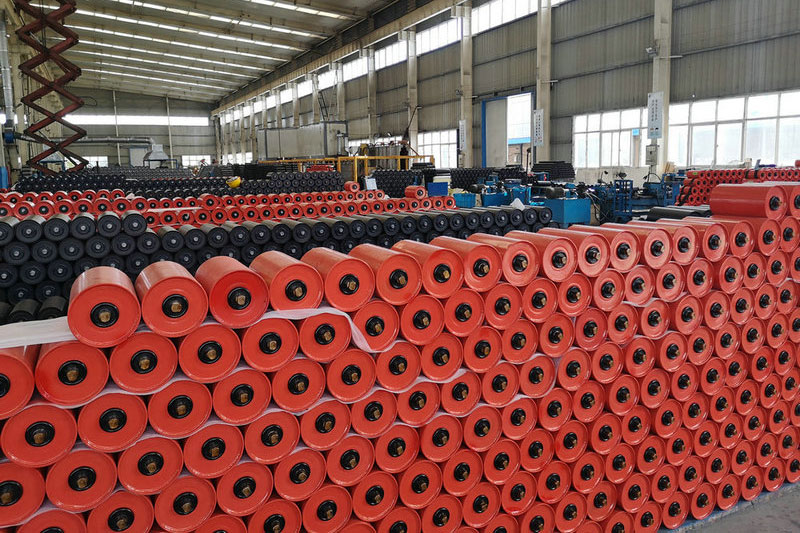

Moontain’s DTII Fixed Belt Conveyor is a modernized and optimized version of the traditional DT75 conveyor system. Engineered to meet the demanding requirements of in-plant bulk material handling, the DTII series delivers improved structural composition, cutting-edge technology, and reliable performance in various industrial settings.

Designed with flexibility and efficiency in mind, these conveyors are widely used in power plants, metallurgy, mining, ports, cement, and chemical industries. The system allows for smooth and continuous transport of materials over short or long distances within the plant, enhancing productivity and operational safety.

Key features of Moontain DTII Fixed Belt Conveyor:

-

Upgraded Design: Compared to the DT75 model, the DTII series adopts a more advanced structural framework, reducing maintenance needs while improving durability and stability.

-

Modular Components: All parts are standardized and interchangeable, making installation and replacement fast and cost-effective.

-

Strong Power Configuration: Equipped with a hydraulic motor drive system that ensures smooth operation under various load conditions.

-

Customizable Options: Dimensions, power, and speed can be tailored to fit different plant layouts and material flow requirements.

Technical Specifications

|

Model |

Total Power |

Track Speed |

Track Power |

Weight |

Dimensions |

|---|---|---|---|---|---|

|

Type 1 |

120–150 kW |

3–12 m/min |

Hydraulic Motor |

65 Tons |

20 × 3.5 × 6 m |

|

Type 2 |

150–200 kW |

3–12 m/min |

Hydraulic Motor |

75 Tons |

20 × 3.5 × 6 m |

|

Type 3 |

200–270 kW |

6 m/min |

Hydraulic Motor |

85 Tons |

27 × 4.5 × 7.5 m |

Note: Specifications may be adjusted according to the final technical design without prior notice.