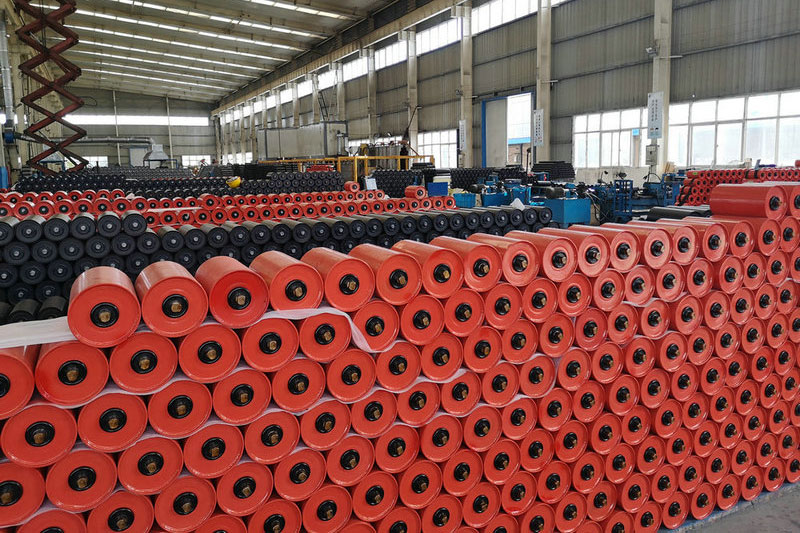

Drum pulleys are critical components in belt conveyor systems, playing a key role in ensuring stable belt movement and optimal system performance. At Moontain, we engineer and manufacture high-performance pulleys designed for durability, reliability, and low maintenance in demanding industrial environments.

Our drum pulleys offer the following advantages:

• Advanced Engineering Design

Using state-of-the-art finite element analysis (FEA), Moontain ensures each pulley is structurally optimized for load-bearing and long-term performance under real-world conditions.

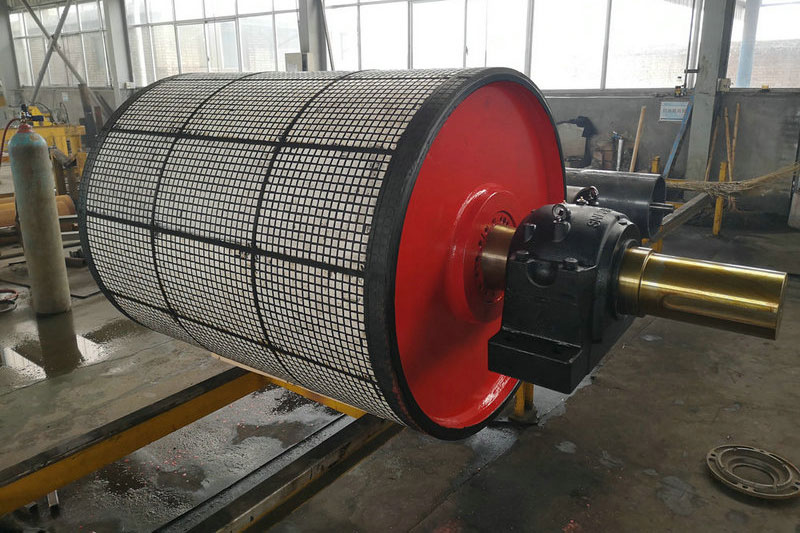

• Premium Lagging Options

To enhance friction and reduce slippage, our pulleys are available with hot vulcanized rubber or ceramic lagging, offering superior wear resistance and improved belt traction.

• Precision Dynamic Balancing

Each pulley undergoes dynamic balancing to minimize vibration, reduce noise, and extend the service life of both the pulley and the conveyor belt system.

• High-Quality Materials

We use only top-grade materials for shells and shafts, ensuring high strength, corrosion resistance, and long-term operational reliability in harsh working environments.

• Optimized Welding Technology

With automated welding for superior consistency and strength, our pulleys feature fewer welds on cast end discs, reducing stress concentration and enhancing structural integrity.