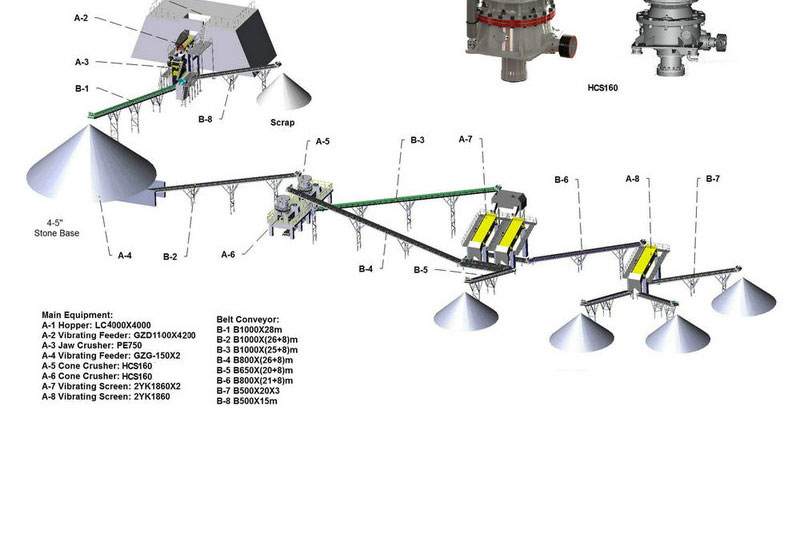

Based on the engineering background of overland/underground belt conveyors, Engineering and Project Management is our core competitiveness, we have participated in both domestic and international projects for belt conveyors and bulk material system.

1) Concept design

2) Budget proposal

3) Basic and detail engineering.

4) Supervision and Site Service

The key person in charge of our company are experienced engineers in this field with more than 15 years working experience, our past working experience cover from the market activity technical consultancy, proposal preparing, bidding submission,procurement management,delivery arrangement, site service,etc. Meanwhile, we have participated projects with owner,EPC contractors and partners in more than 10 countries including project in Australia, Brazil, Chile, Canada,Indonesia,Iran,Mongolia,Pakistan,Philippine,Poland, South Korea, Vietnam,United States, etc.

If you need more details, pls feel free to contact: [email protected]