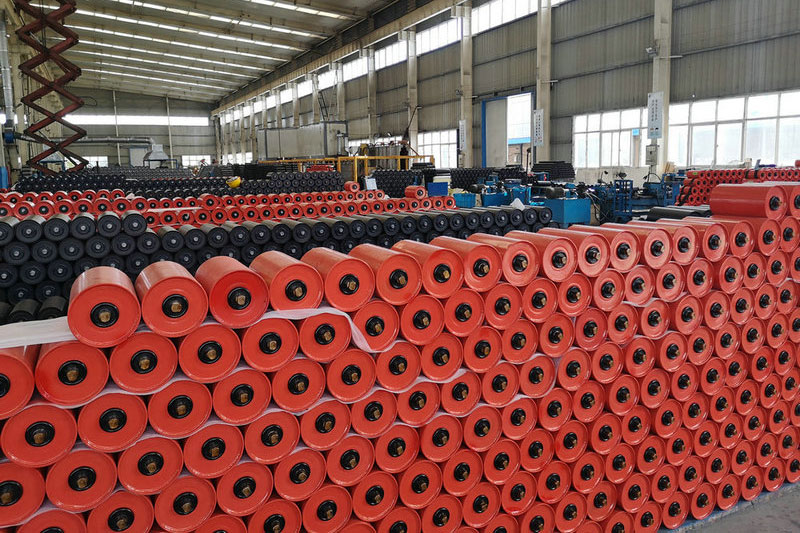

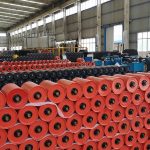

Moontain’s Impact (Rubber) Rollers are specially designed to absorb impact forces and protect the conveyor belt from damage during material loading. Featuring a high-performance rubber surface and robust internal structure, these rollers play a vital role in extending belt life and improving system efficiency.

Key Features & Advantages

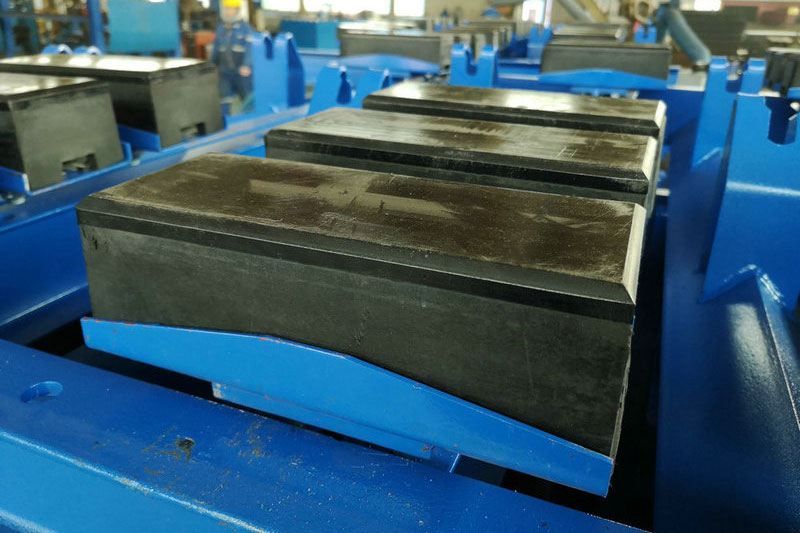

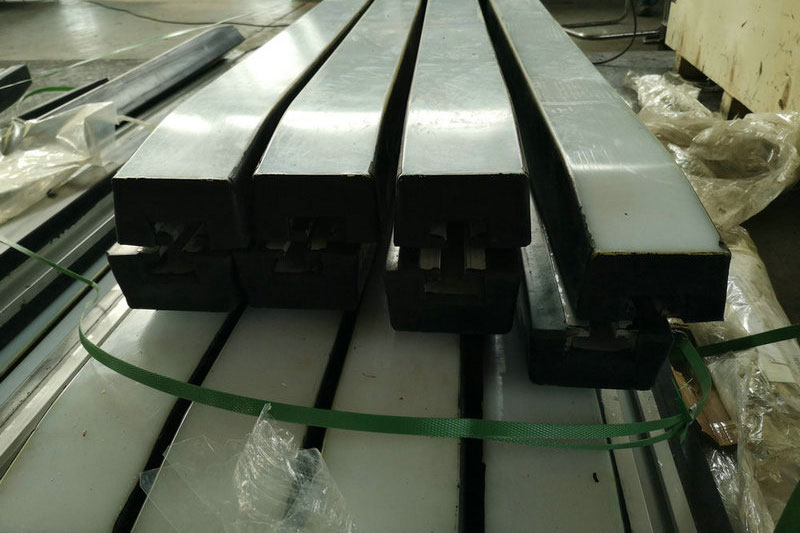

➤ Impact Bars for Superior Cushioning

Each roller incorporates high-resilience impact bars that effectively cushion heavy or sharp materials, minimizing sudden shocks during loading.

➤ Prevents Belt Damage

Reduces the risk of tearing, gouging, or scratching caused by sharp or heavy materials—particularly at material transfer or drop zones.

➤ Strategic Installation Points

Ideal for placement under belt conveyor loading zones, material guide chutes, and impact areas where material drops onto the belt.

➤ Low Friction Coefficient

Ensures smooth belt travel with minimal resistance, helping to maintain consistent belt tracking and reduce power consumption.

➤ Excellent Shock Absorption Performance

Designed to withstand continuous high-impact operations, even in abrasive and heavy-duty environments.

Typical Applications

•Mining and Quarrying

•Aggregate and Cement Industries

•Bulk Material Transfer Points

•Ports and Terminals

•Heavy-load Conveyor Systems

Why Choose Moontain Impact Rollers?

Engineered for long-lasting performance and tailored to high-impact environments, Moontain’s rubber-coated impact rollers are a crucial component for any conveyor system that handles bulk, abrasive, or sharp materials. Enhance the safety and longevity of your equipment with our proven impact roller solutions.