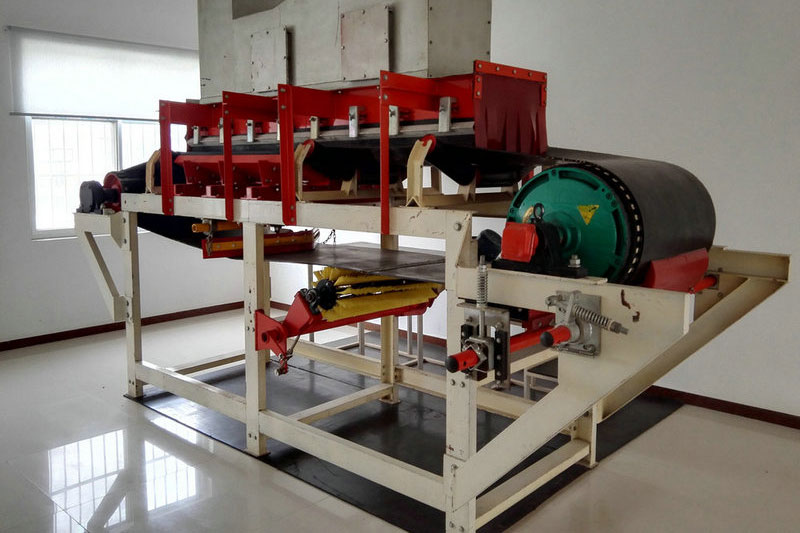

Moontain Secondary Belt Cleaners are essential equipment in industries that involve medium to heavy-duty conveyor systems. Specifically designed for applications such as aggregate handling, sand and gravel processing, cement production, fertilizer manufacturing, port operations, and underground mining, these belt cleaners are engineered to efficiently remove carryback material from the conveyor belts.

The choice of suitable secondary belt cleaners depends on several factors, including the belt speed, pulley diameter, and condition of the materials being transported. Moontain offers a wide range of secondary belt cleaners that can be customized to meet the specific requirements of different industries and applications.

Benefits of Moontain Secondary Belt Cleaners

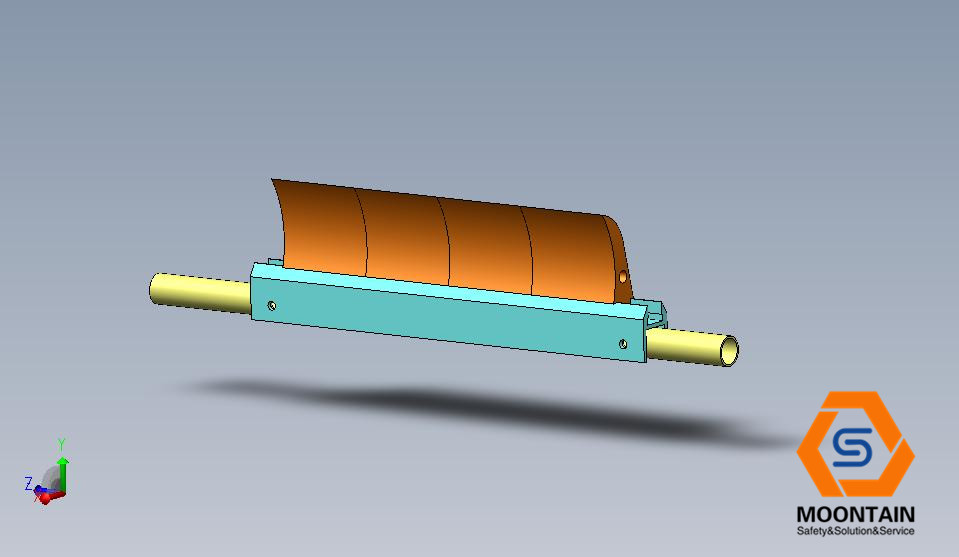

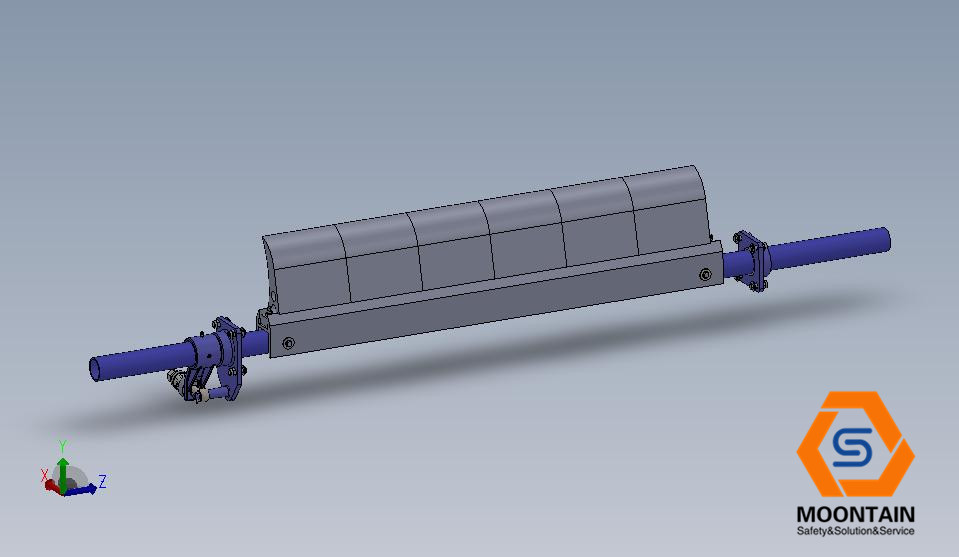

1. Efficient Material Removal: Moontain Secondary Belt Cleaners effectively remove carryback material from the conveyor belt, preventing spillage and buildup along the system. This helps to maintain a clean and efficient conveyor operation, reducing maintenance costs and improving overall productivity.

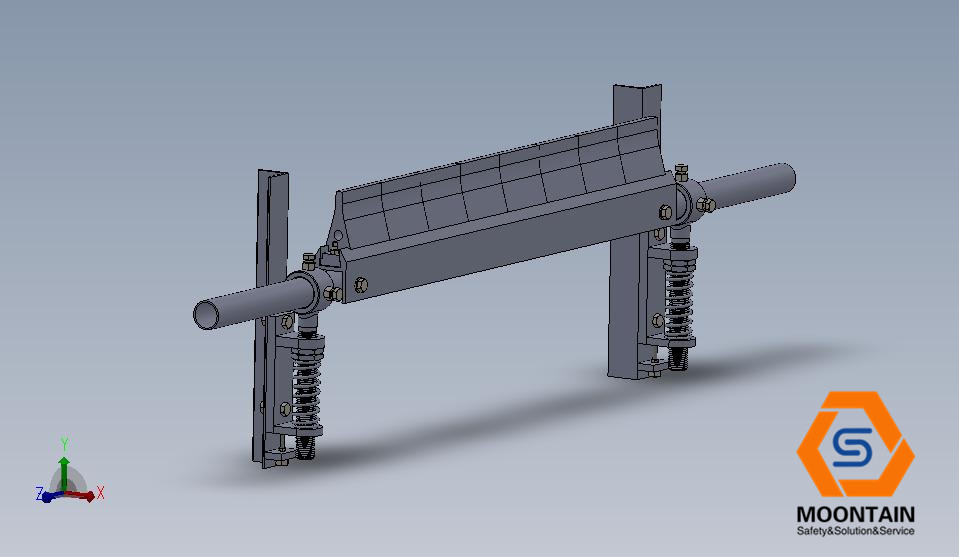

2. Versatility: These belt cleaners are designed to be adaptable to various conveyor systems, including troughed, flat, and inclined belts. They can handle different material types and particle sizes, making them suitable for a wide range of applications.

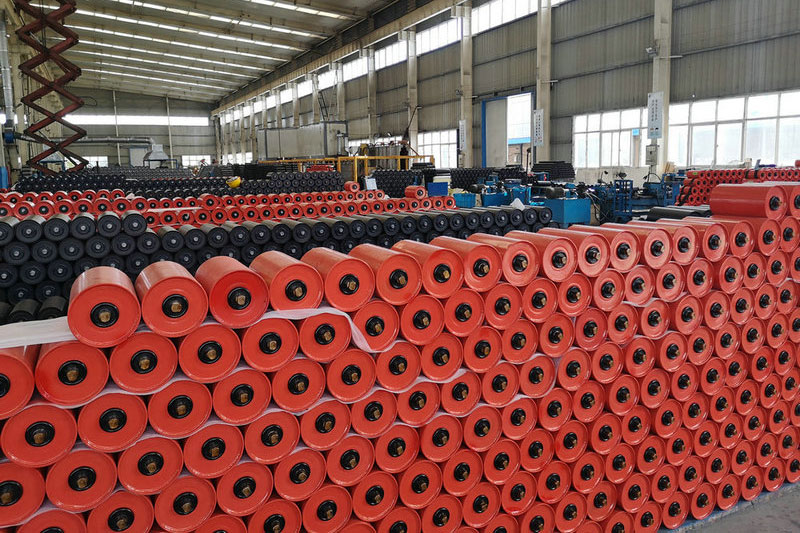

3. Durable Construction: Moontain Secondary Belt Cleaners are built to withstand the rigors of heavy-duty operations, ensuring long-lasting performance even in harsh environments. They are made from high-quality materials that offer excellent wear resistance and durability.

4. Easy Installation and Maintenance: These belt cleaners are designed for easy installation and maintenance, minimizing downtime and improving operational efficiency. They can be quickly and conveniently adjusted or replaced to ensure optimal cleaning performance.

Moontain Conveyor Belt Cleaning Solutions

Moontain Secondary Belt Cleaners provide an effective solution for improving conveyor system performance in industries that deal with medium to heavy-duty materials handling. With their efficient material removal capabilities, versatility, and durable construction, these belt cleaners contribute to reduced maintenance costs, improved productivity, and enhanced overall operational efficiency. Trust Moontain to deliver reliable and innovative solutions for your conveyor belt cleaning needs.