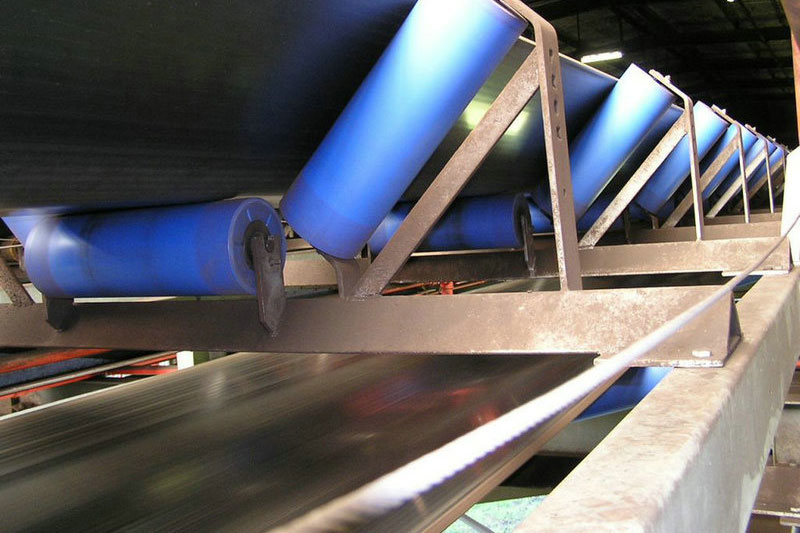

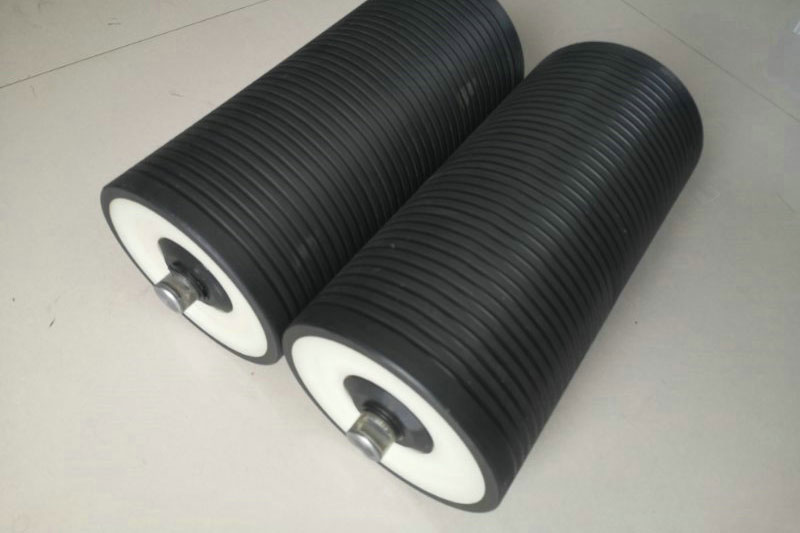

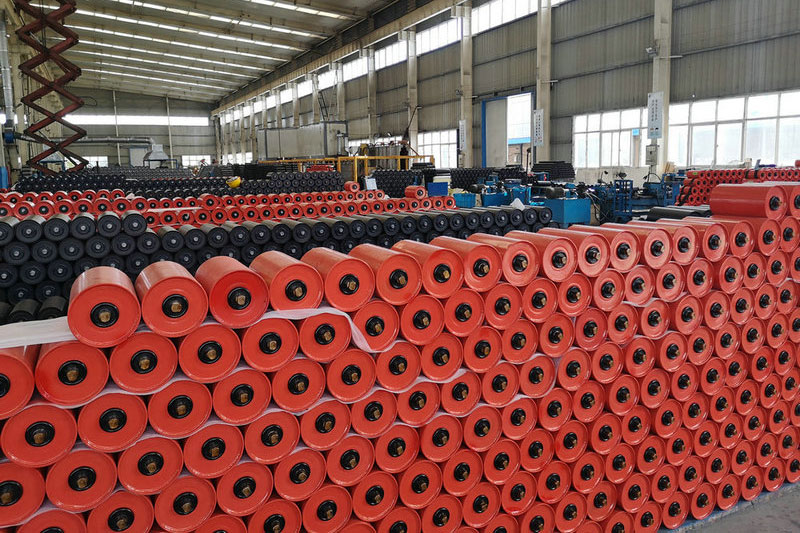

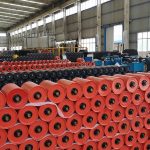

Moontain’s HDPE (High-Density Polyethylene) Rollers are designed to outperform traditional steel rollers in the most demanding environments. Lightweight, corrosion-resistant, and highly durable, they provide a cost-effective and energy-efficient solution for modern conveying systems.

Advantages

➤ Exceptional Abrasion Resistance

Built to handle abrasive materials with minimal wear, extending roller life even in harsh applications.

➤ Extended Service Life

Non-corrosive and resistant to impact and chemical exposure, significantly reducing replacement frequency.

➤ Up to 40% Lighter Than Steel

Reduces overall conveyor weight, making installation easier and decreasing stress on the conveyor structure.

➤ Lower Start-up Power Requirements

Lightweight design leads to reduced torque on start-up, minimizing energy consumption and prolonging drive component life.

➤ Reduced Maintenance Costs

HDPE rollers do not rust, dent, or seize, decreasing maintenance downtime and operating expenses.

➤ Protects Conveyor Belts

Low-friction surface minimizes belt wear and helps prevent costly belt damage.

➤ Superior Energy Efficiency

Lower rolling resistance translates into improved operational efficiency and reduced power usage.

➤ Performs in Harsh & Extreme Conditions

Withstands exposure to moisture, dust, chemicals, and temperature fluctuations—ideal for tough industrial environments.

Application

•Iron Ore & Hard Rock Mining

•Gold Mining

•Fertilizer Plants

•Bauxite Handling

•Cement & Aggregate Industries

•Any extreme, moist, corrosive, or dusty environment

Moontain’s HDPE Rollers represent a robust, long-lasting, and environmentally responsible alternative to traditional steel rollers. Whether you’re upgrading an existing conveyor system or building a new one, our HDPE rollers deliver reliable performance where it matters most.