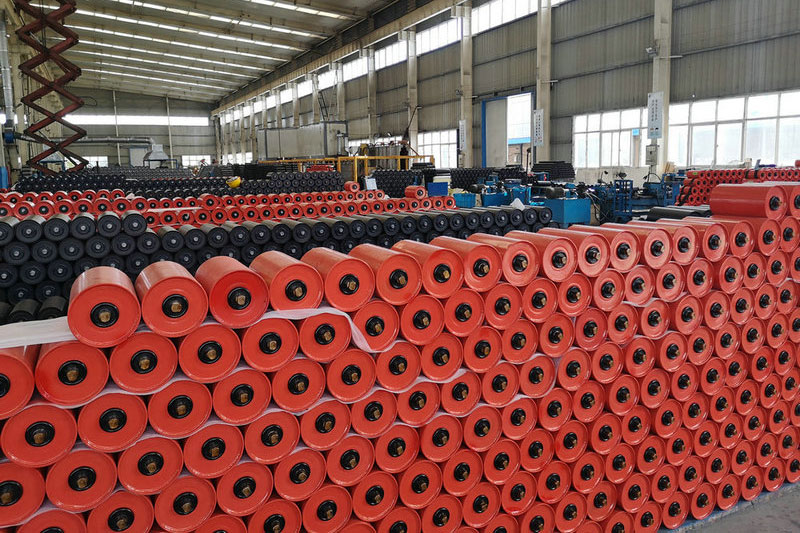

Moontain’s pipe belt conveyor system represents a cutting-edge solution for the environmentally responsible and efficient transport of bulk materials. With its fully enclosed design, it minimizes dust emissions, reduces noise levels, and lowers operational labor requirements—making it the ideal choice for both outdoor and in-plant applications.

This system is especially effective in facilities where space is limited, where sharp turning radii are required, or where vertical drops and degradation of materials must be avoided. The tubular structure ensures that materials are transported safely without spillage, even along complex curved routes and steep inclines.

Today, Moontain’s pipe conveyor technology stands at the forefront of the industry. We have successfully completed numerous large-scale projects across various sectors, including notable installations for Wuhan Steel Group, Henan Petrochemical Company, and the Central Power Plant.

Key Features of Moontain Pipe Belt Conveyors

-

Fully Enclosed Material Transport

Prevents dust, spillage, and contamination while keeping the material isolated from external environmental conditions.

-

Weather-Resistant and Environmentally Friendly

The enclosed system ensures reliable operation in all weather conditions, promoting cleaner, greener industrial processes.

-

Long-Distance and Curved Conveying

Capable of transporting materials over extended distances with horizontal and vertical curves, eliminating the need for multiple transfer points.

-

Bi-Directional and Steep Incline Capability

Supports reversible conveying and accommodates steep gradients, offering flexible layout options for complex plant environments.

Moontain continues to innovate in the field of bulk material handling, delivering customized pipe conveyor systems that meet the evolving needs of modern industries.